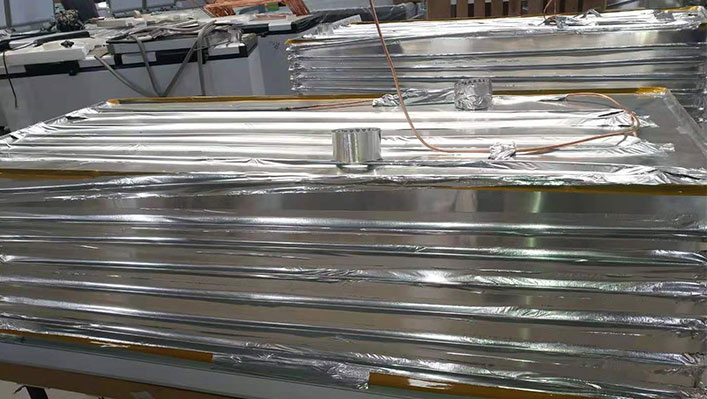

Aluminum foil tapes play a crucial role in various aspects of refrigeration systems due to their unique properties and characteristics. Usually in the refrigeration market, HVAC aluminum foil tapes are used to attach tubes, channels or coils expanding the area of thermal exchange. Here are some key applications of aluminum foil tapes in refrigeration systems:

1. Sealing and Insulating Ducts: Aluminum foil tapes are often used to seal and insulate air ducts in refrigeration systems. They provide a strong, airtight seal that helps prevent air leakage, ensuring efficient cooling and heating operations.

2. Repairing HVAC Components: These tapes are used for repairing damaged or leaking HVAC components such as refrigerant lines, coils, and joints. The high-strength adhesive and heat-resistant properties of aluminum foil tapes make them ideal for such applications.

3. Thermal Insulation: Aluminum foil tapes are excellent thermal insulators. They are used to wrap pipes, valves, and other components in refrigeration systems to prevent heat transfer, maintain temperature stability, and improve energy efficiency.

4. Moisture Barrier: Aluminum foil tapes act as an effective moisture barrier, protecting refrigeration system components from moisture ingress and corrosion. They are commonly used to seal seams and joints in insulation materials to prevent moisture penetration.

5. Vibration Damping: In refrigeration systems, vibrations from compressors, fans, and other components can cause noise and damage. Aluminum foil tapes are applied to dampen vibrations and reduce noise levels, improving the overall performance and longevity of the system.

6. Reflective Shielding: Aluminum foil tapes are highly reflective, making them suitable for applications where heat reflection is required. They are used to line the interior of refrigeration units or enclosures to reflect radiant heat and maintain optimal temperature conditions.

7. Cable Shielding: In refrigeration systems with electronic components, aluminum foil tapes are used for electromagnetic interference (EMI) shielding. They are applied around cables and wiring to prevent interference from external sources, ensuring reliable operation of sensitive equipment.

8. HVAC System Maintenance: Aluminum foil tapes are essential for routine HVAC system maintenance tasks such as sealing gaps, patching leaks, and securing insulation. They help maintain system efficiency, prolong equipment life, and reduce energy consumption.

In order to increase the thermal efficiency in refrigerators, the appliance industries extensively used HVAC aluminum foil tapes to wrapping tubes inside refrigerators.

Overall, aluminum foil tapes are versatile and indispensable components in refrigeration systems, offering reliable sealing, insulation, protection, and thermal management properties. Their durability, flexibility, and ease of use make them a preferred choice for various applications in the HVAC and refrigeration industry.