- Tapes by Type

-

Tapes by Application

- About

By reducing radiant heat gain, acting as a vapor barrier, and providing flame retardancy, our insulation facing products, including various types of foil faced insulation and kraft faced insulation, contribute to achieving better energy efficiency and effective condensation control in a wide array of applications.

Our comprehensive selection of insulation facing products includes specialized options like foil faced insulation and kraft faced insulation, each designed for specific performance requirements:

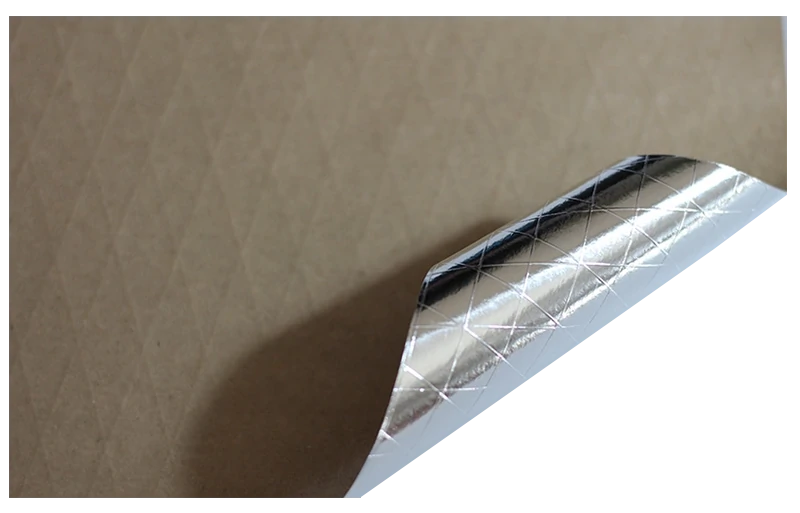

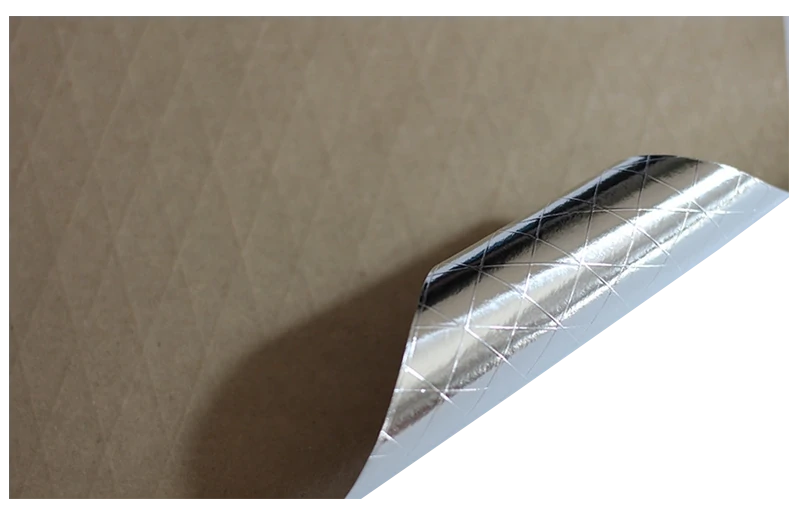

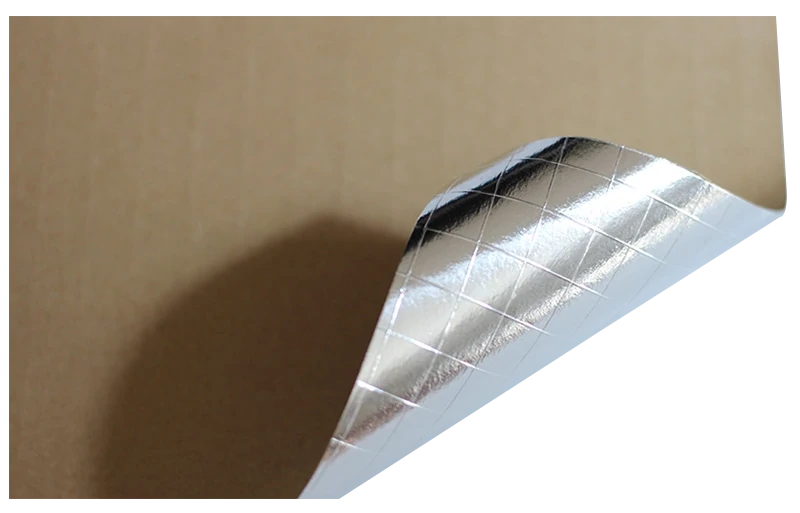

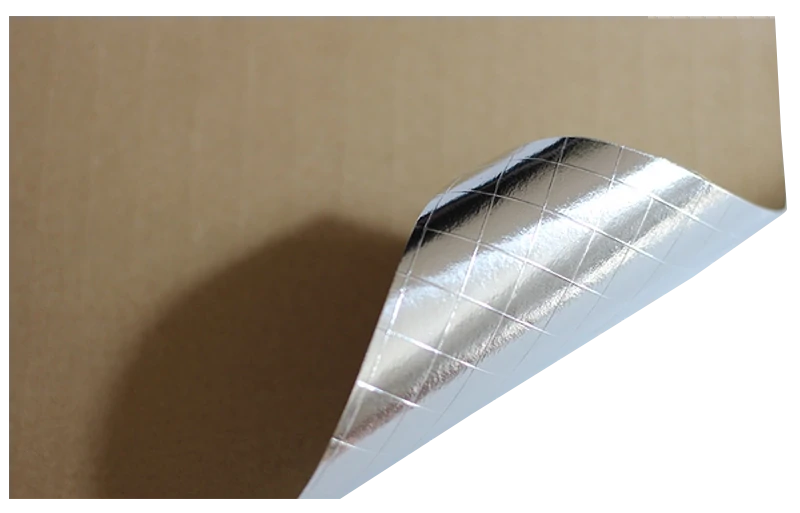

Reinforced heat-reflective insulation facing, 18u aluminum foil, 8×8 mesh/cm glass cloth as well as heat-activated polyethylene

Aluminum foil facing, enhance insulation, fire safety, and energy efficiency in residential, commercial & industrial applications

18u foil and 8×8 mesh glass cloth, laminated with F/R glue, UL 723 & BS 476 Pt 6&7 Fire rating approval

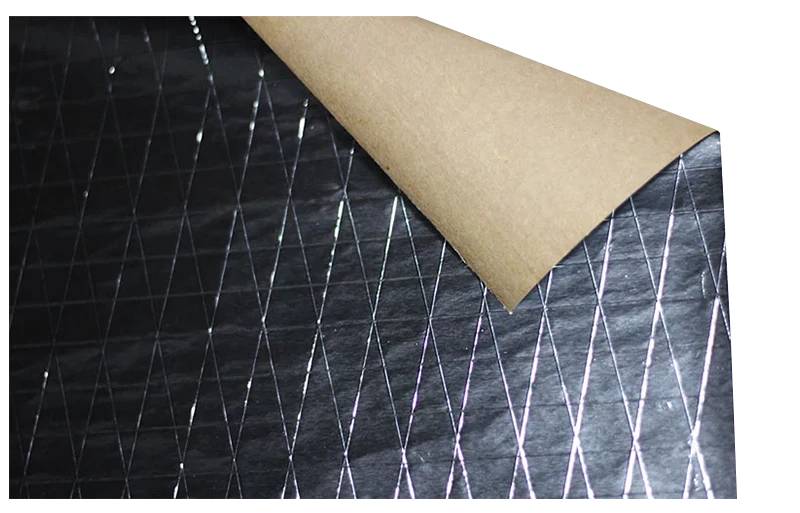

Durable foil-kraft-scrim vapor barrier insulation, with a 3-way scrim and 50gsm Kraft as well as heat-activated polyethylene on its back

Premium insulation facing and vapor barrier solution, 3-way scrim and 60gsm Kraft as well as heat-activated polyethylene on its backing

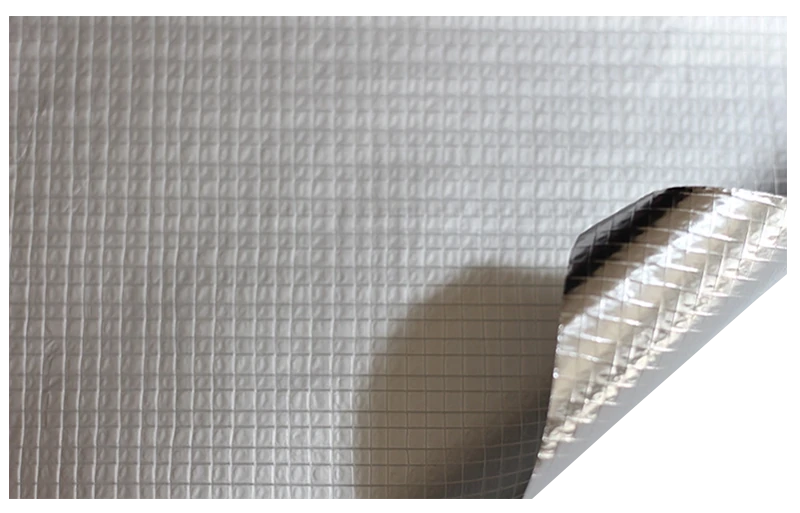

15u foil and 2-way scrim (5x5mm spacing) with heat-activated polyethylene on its back

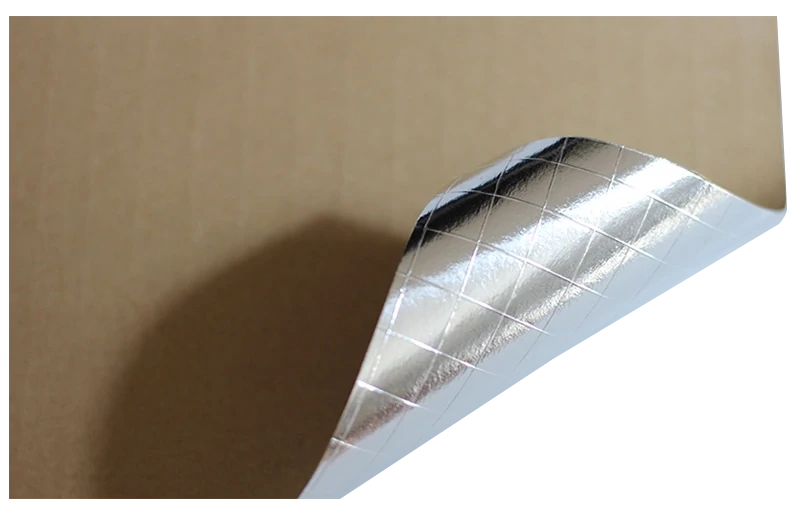

Durable, lightweight and cost-effective insulation material, 18u foil and 2-way scrim with heat-activated polyethylene on its backing

F/R grade Foil-Scrim-Kraft Facing with 2-way scrim and 60gsm Kraft (F/R treated)

Premium grade Foil-Scrim-Kraft facing with 3-way scrim and 80gsm Kraft, ideal for insulation projects

Premium grade Foil-Scrim-Kraft facing for construction and HVAC systems, effective moisture, vapor, and heat protection

Fire resistant grade Foil-Scrim-Kraft facing with 3-way scrim and 60gsm Kraft. Durable and efficient.

Utility grade Heat-sealing Foil-kraft-scrim Facing with 2-way scrim and 50gsm Kraft, suitable for HVAC & metal buildings insulation