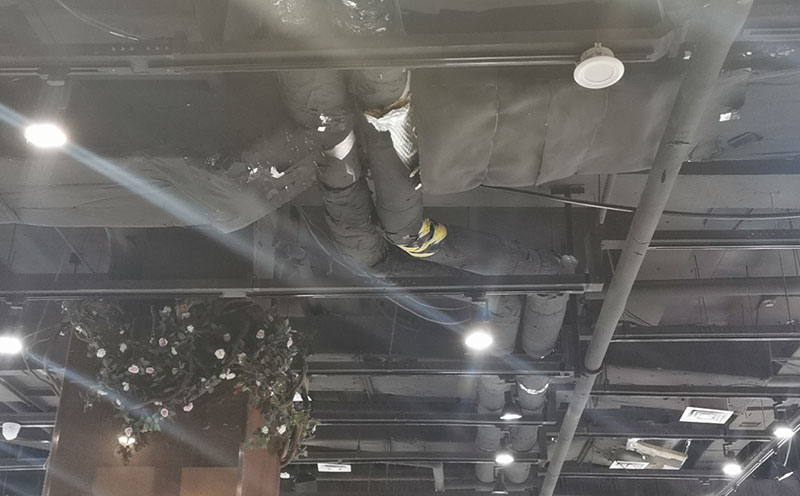

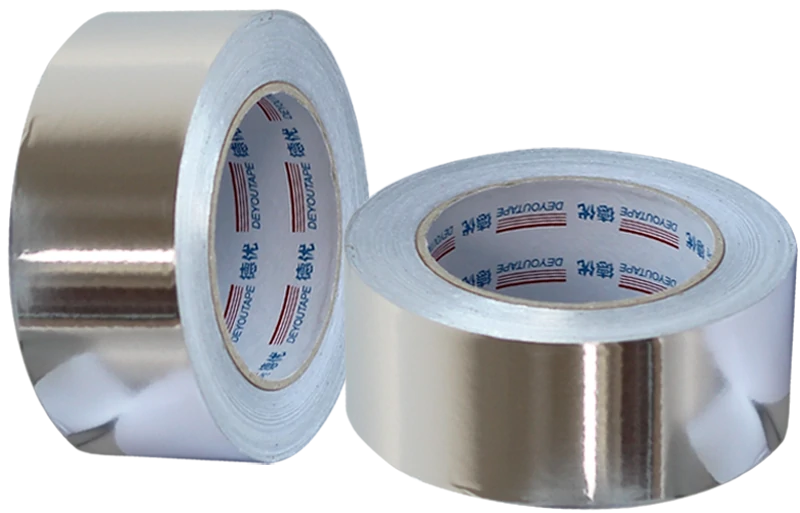

HVAC systems stands for Heating, Ventilation, and Air Conditioning. It refers to the systems that control the temperature, humidity, and air quality in a building. HVAC systems are essential for providing indoor comfort by regulating the humidity, air quality, and temperatures. If you’re tackling an HVAC job, foil HVAC tape should be your go-to.

Benefits for using foil HVAC tape:

1. Heat and Light Reflection: The aluminum foil backing of the tape reflects heat and light, which can help in maintaining temperature control and energy efficiency within HVAC systems.

2. Sealing: Foil HVAC tape is effective for sealing joints and seams in ductwork, preventing air leaks and ensuring the efficient operation of the HVAC system.

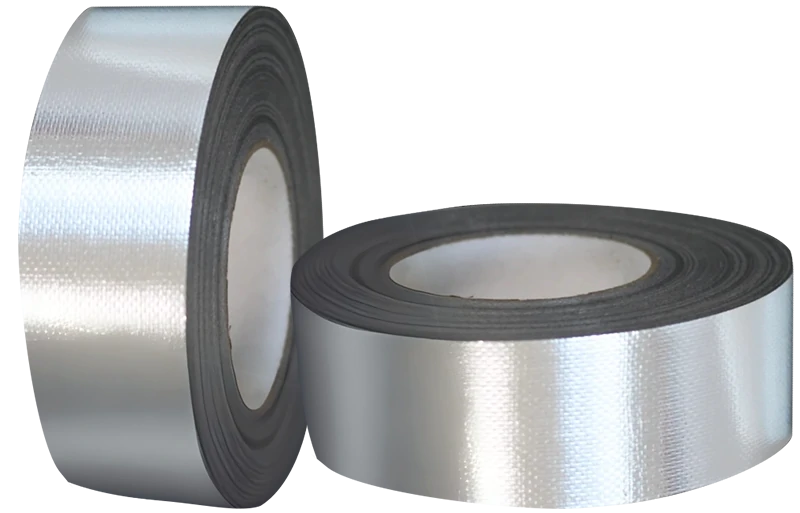

3. Insulation: It can be used to secure insulation materials in HVAC applications, providing a protective barrier and enhancing the overall insulation performance.

4. Heat and Moisture Resistance: Aluminum foil tape is resistant to high temperatures and moisture, making it suitable for use in HVAC systems where these conditions are common.

5. Durability: Foil HVAC tape is made from tough aluminum and a strong adhesive, making it resistant to rips, punctures, and tears. This durability ensures a long-lasting seal, even in demanding environments like ductwork.

6. Compatibility: Foil HVAC tape is compatible with a variety of HVAC materials, including metal ducts and insulation, making it versatile for different HVAC applications.

7. Versatility: Foil tape can be used for a variety of applications within your HVAC system, including:

Sealing seams and gaps in ductwork.

Patching small holes or tears in ducts, pipes, or insulation.

Wrapping hot water pipes or appliance housings for insulation.

Securing loose wires or components.

Creating temporary seals or covers.

Overall, foil HVAC tape is valued for its ability to provide effective sealing, thermal insulation, and durability in HVAC systems, making it an essential component for maintaining the efficiency and functionality of HVAC installations. However, it's important to note that foil tape isn't a perfect solution for every situation in your HVAC system. Here are some limitations to consider:

Not suitable for high temperatures: While foil tape can withstand most common HVAC temperatures, it might not be appropriate for areas exposed to extreme heat, as the adhesive can become weak or melt.

Not as strong as other materials: For permanent repairs or high-pressure areas, thicker materials like sheet metal or mastic might be a more suitable option.

Adhesive failure: Over time, the adhesive on foil tape can degrade, especially if exposed to moisture or extreme temperatures.