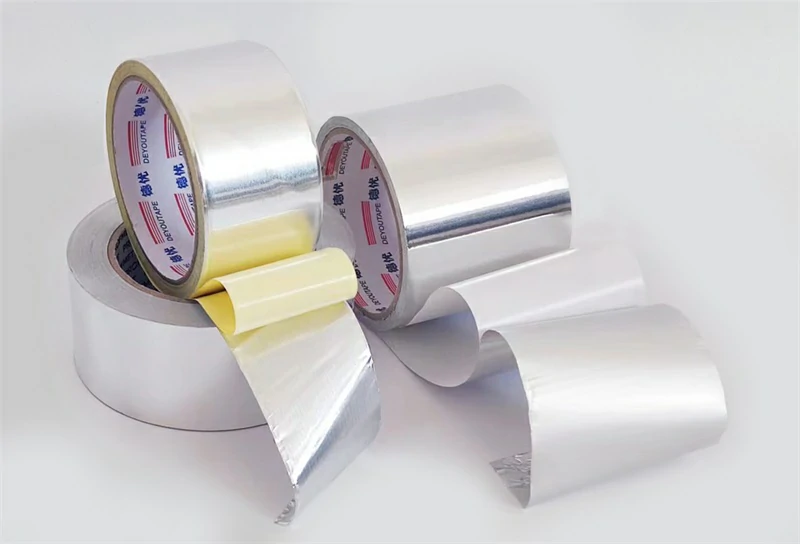

Aluminum foil tape is a versatile material commonly used in HVAC systems due to its reflective properties, heat resistance, and moisture barrier qualities. It is common used for sealing and patching ductwork, insulation, and other components in HVAC systems. The best foil tape for HVAC applications is typically a high-quality aluminum foil tape with a strong adhesive and excellent temperature resistance. When choosing the best aluminum foil tape for HVAC (Heating, Ventilation, and Air Conditioning) applications, it's important to consider several factors that affect performance and durability.

Key Features to Consider

1. Adhesive Quality : The tape should have a high-quality adhesive that can withstand a range of temperatures and humidity levels. It should stick well to both metal and insulation surfaces.

2. Temperature Tolerance: HVAC systems can experience a wide range of temperatures. The tape should perform well under extreme temperatures without losing adhesion or degrading. Our extensive selection of foil tapes can withstand temperatures from -22°F to 248°F. It can be applied to products in temperatures from 14°F to 104°F.

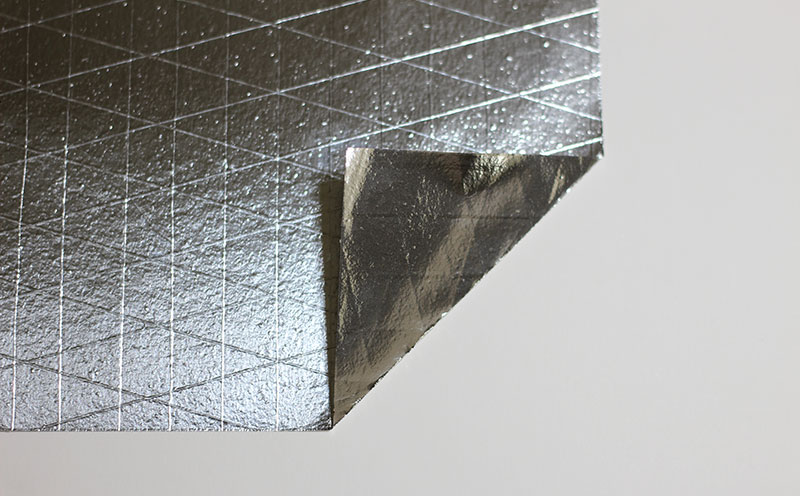

3. Moisture Resistance: It should be resistant to moisture and humidity to prevent it from peeling off or deteriorating, which is crucial in ductwork that may be exposed to condensation.

4. Thickness and Durability: Thicker tapes generally offer better durability, punctures and sealing capabilities. They are less prone to tearing during application and can handle more wear and tear, to ensure it can withstand the rigors of HVAC use.

5. UL Certification: Look for tapes that are UL 181 rated, as this indicates they meet specific fire codes and standards for HVAC systems. DeYou UL-723 aluminum foil duct tape is especially resistant to harsh chemicals, which makes it ideal in extreme conditions where saltwater, oil, fuel, and corrosive chemicals are found.

6. Ease of Application : The tape should be easy to apply and conform to irregular surfaces without wrinkling or tearing, and provide a tight seal around ductwork and other HVAC components.

Recommended Types of Aluminum Foil Tape for HVAC:

1. High-Temperature Aluminum Foil Tape: Specifically designed for HVAC applications, these tapes can withstand temperatures up to 400°F or higher.

2. Butyral Rubber-Based Aluminum Foil Tape: Offers good adhesion and moisture resistance, making it suitable for sealing ductwork and joints.

3. Silicone-Based Aluminum Foil Tape: Provides excellent heat resistance and flexibility, making it ideal for use in high-temperature environments.

DeYou UL-723 aluminum foil tape is widely used in all kinds of industries, from manufacturing to construction. Thanks to its moisture and chemical resistance, thermal conductivity, flame resistance, heat and light reflectance, and weather ability. We engineered our foil tapes to have all the qualities of aluminum with the added benefit of an aggressive and long-lasting adhesive.

Application Tips

Surface Preparation: Ensure surfaces are clean, dry, and free of dust or grease for the best adhesion.

Proper Application: Apply with enough pressure to remove any air pockets and ensure a firm bond.

Overlap Seams: When sealing ducts, overlap the tape seams to improve the seal and increase durability.

Selecting the right aluminum foil tape for your HVAC system can significantly impact its efficiency and functionality. Consider the specific requirements of your application, including the environmental conditions and the surfaces to which the tape must adhere, to choose the most appropriate product.