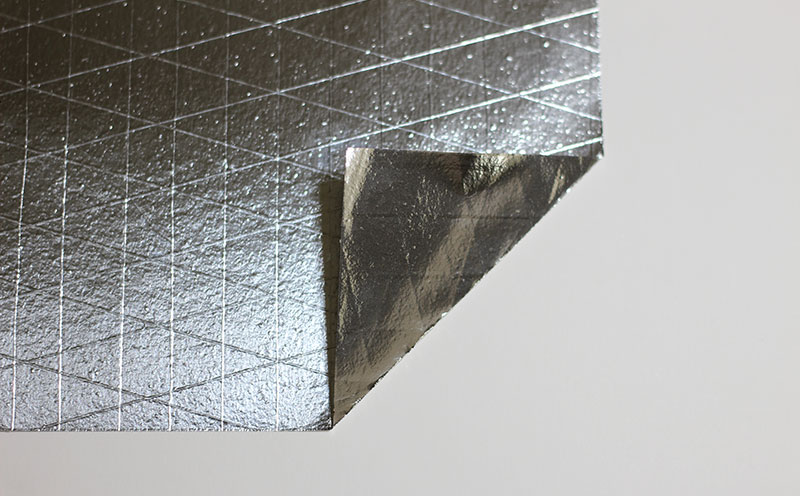

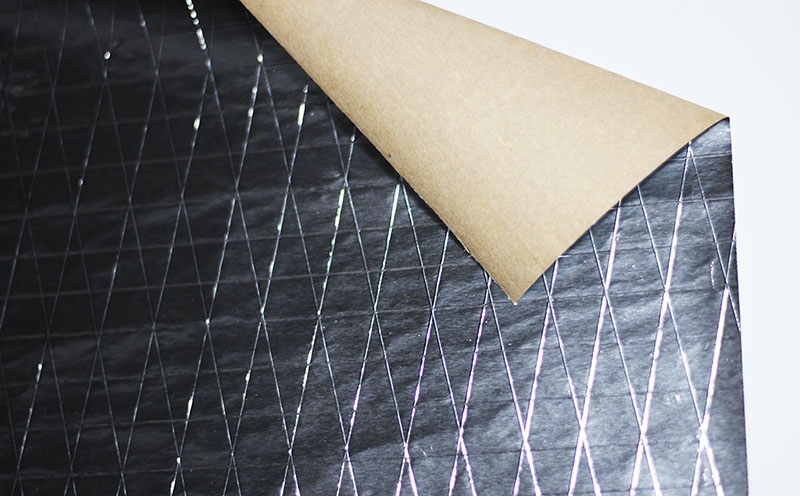

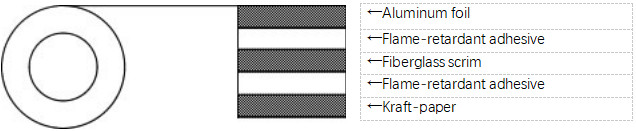

FSK: Foil-scrim-kraft, Scrim=Yarn

FSK insulation facing, also known as Foil-Scrim-Kraft facing, is a type of insulation facing material commonly used in commercial and residential construction. Its typical using is as insulation material in HVAC (Heating, Ventilation, and Air Conditioning) systems. FSK Insulation facing is an outer surface of insulation materials, it is additional layer made of reinforced Aluminum foil or PP film. Foil-scrim-kraft insulation facing is an insulation product that is both a vapor barrier and a flame retardant.

FSK Insulation facing is laminated 5 layers of structure, the outer layer is Aluminum foil and Kraft paper. The middle layer is the Glass fiber layer double side coated with Flame-retardant adhesive, it increased tensile strength of FSK, and the Aluminum foil and Kraft paper are firmly bonded. It consists of three main components:

Foil: The outer layer is typically made of aluminum foil, which provides a reflective surface. This foil layer helps to reduce radiant heat transfer, improving the overall insulation efficiency. The aluminum foil layer effectively blocks moisture vapor from entering or leaving the building through the insulated wall or ceiling cavity. This is crucial for preventing condensation buildup and the associated problems like mold growth and structural damage.

Scrim: The middle layer is a reinforcing mesh or fabric, usually made of fiberglass. The scrim adds strength and durability to the facing, making it more resistant to tearing or puncturing.

Kraft: The inner layer is made of kraft paper, which provides additional structural support and serves as a vapor retarder. The kraft paper helps prevent moisture transmission through the insulation, preventing condensation and potential damage to the underlying materials. It also has flame-retardant properties, contributing to the overall fire safety of the insulation.

FSK insulation facing has a vapor barrier or a vapor retarder (the facing) that helps prevent moisture from moving from one space to another. The facing also helps protect the surface, hold the insulation together and fasten the material to building components. FSK Insulation Facing is typically lightweight and flexible, making it easy to handle and install. It can be easily cut to size and securely attached to insulation materials using adhesives or mechanical fasteners.

Benefits of Using FSK Insulation Facings

FSK (Foil Scrim Kraft) insulation facings offer several advantages in various applications, particularly in HVAC systems and construction. Here are some of the key benefits:

Improved Energy Efficiency

Reflective properties: The aluminum foil layer in FSK reflects heat, reducing heat transfer and improving energy efficiency.

Vapor barrier: FSK acts as a vapor barrier, preventing moisture from entering the insulation and causing condensation or mold growth.

Enhanced Durability

Protection: The facing protects the insulation material from damage, ensuring its longevity.

Strength: The scrim layer adds strength and durability to the insulation.

Moisture Control

Vapor barrier: Prevents moisture from entering the insulation, reducing the risk of mold and mildew growth.

Condensation control: Helps to prevent condensation on cold surfaces, which can lead to energy loss and structural damage.

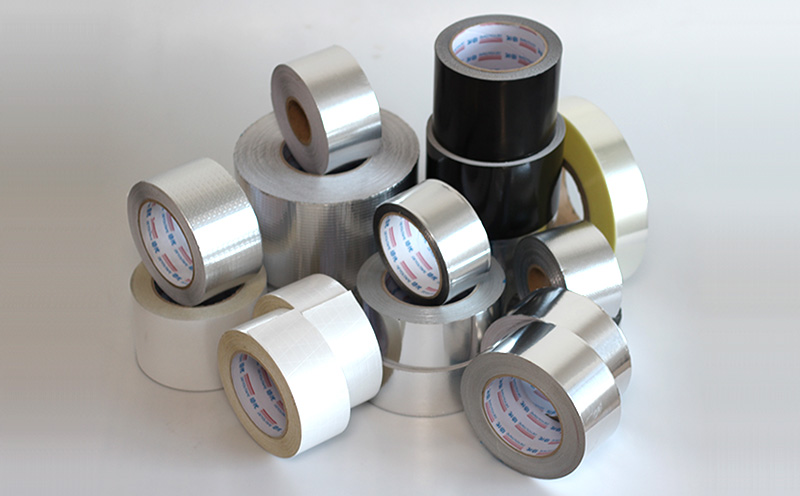

Ease of Installation

Fast and efficient: FSK facings are easy to handle and install, saving time and labor costs.

Versatility

Wide range of applications: FSK facings can be used in various applications, including HVAC ducts, pipe insulation, and attic insulation.

Fire Resistance

Flame-retardant properties: FSK facings are often flame-retardant, providing additional safety.

Overall, FSK insulation facings offer a combination of energy efficiency, durability, moisture control, and ease of installation, making them a popular choice for various applications.

Disadvantages of FSK Insulation Facing:

Not breathable: Can trap moisture within the wall cavity if not properly installed with adequate ventilation.

Requires careful handling: The foil layer can be easily damaged during installation.

Less effective in high-humidity environments: May not be ideal for certain locations or applications with very high humidity levels.

Applications of FSK Insulation Facing

FSK (foil-scrim-kraft) insulation facing is widely used in various applications due to its combination of vapor barrier, thermal resistance, and durability properties.

HVAC Systems

Ductwork: FSK is commonly used as a facing material for duct wrap, duct board, and other HVAC components to prevent condensation, improve energy efficiency, and protect the insulation.

Air handlers and coils: FSK can be used to insulate these components, reducing energy consumption and improving system performance.

Building Insulation

Attics: FSK can be used as a vapor barrier and radiant heat barrier in attic insulation systems.

Walls: It can be applied to walls to control moisture and improve insulation efficiency.

Roof decks: FSK can be used as a protective layer over insulation in roof assemblies.

Industrial Applications

Piping insulation: FSK can be used to insulate pipes to prevent heat loss or gain and condensation.

Equipment insulation: It can be applied to various industrial equipment to improve energy efficiency and protect personnel.

Other Applications

Marine and RV insulation: FSK can be used in these applications to provide thermal and moisture protection.

Agricultural and cold storage: It can help maintain temperature and humidity levels in these environments.

Overall, FSK insulation facing is a versatile material that offers important benefits in terms of insulation performance, durability, and moisture control in a variety of applications.

Would you like to know more about specific information for these insulation facings, please contact DeYou’s Experts.