HVAC aluminum foil tape and duct tape are both commonly used in various applications, but they serve different purposes, especially in terms of HVAC system maintenance and repair. When it comes to HVAC systems, choosing the right type of tape for sealing ducts is crucial for ensuring efficiency, durability, and compliance with building codes. Understanding the distinctions between these two types of tape can help in choosing the right one for specific tasks.

The adhesive used in general purpose duct tape is not built to withstand the conditions that HVAC-specific tapes are tested to perform in. Cold and hot temperatures can cause this type of duct tape to flag and fall off, leaving leaks in the system that can result in energy loss and expensive heating and cooling bills.

Some people use duct tape for insulation, but foil tape is more effective because it better resists the elements. Aliminum foil tape maintains its integrity even when affixed to heated insulation materials, while the adhesive in duct tape can deteriorate over time, especially if exposed to high temperatures.

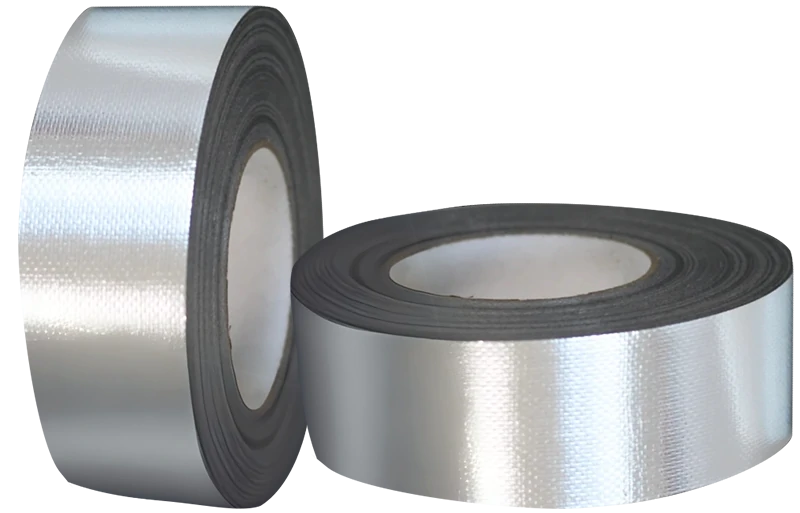

Duct Tape

-

Duct tape is a single-faced adhesive tape of polyethylene (PE) laminated spun rayon cloth backing which is coated by rubber pressure-sensitive adhesive (PSA).

Duct tape has outstanding adhesion power, keeping the merit of easy to tear and good performance in Ducting, Fixing and Labeling for different colors. But duct tape does not perform well under extreme temperatures and can degrade when exposed to heat or cold for extended periods. It offers moderate moisture resistance but is not as effective as aluminum foil tape in preventing vapor transmission.

Duct tape is versatile for temporary repairs on a range of materials, from plastics to fabrics and even metal, but it is not ideal for permanent solutions. Its also useful for quick, temporary fixes where high durability and long-term performance are not critical. Duct tape is not as durable as HVAC aluminum foil tape and is not recommended for use in HVAC systems.

-

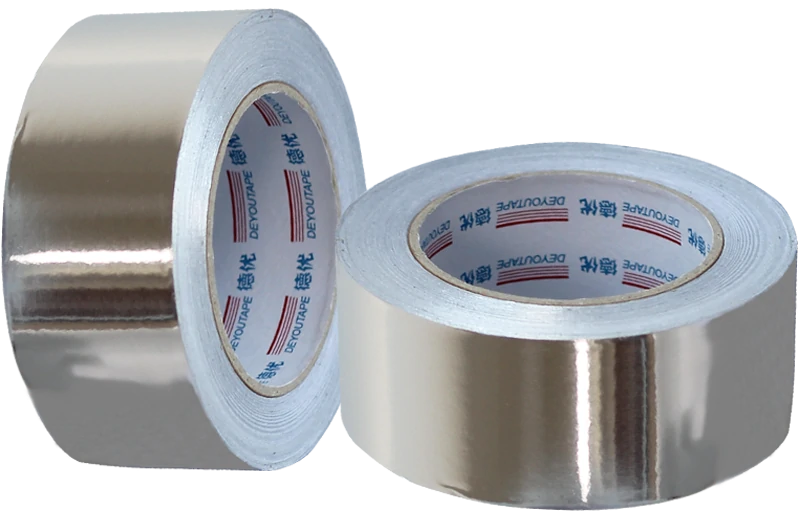

HVAC Aluminum Foil Tape

-

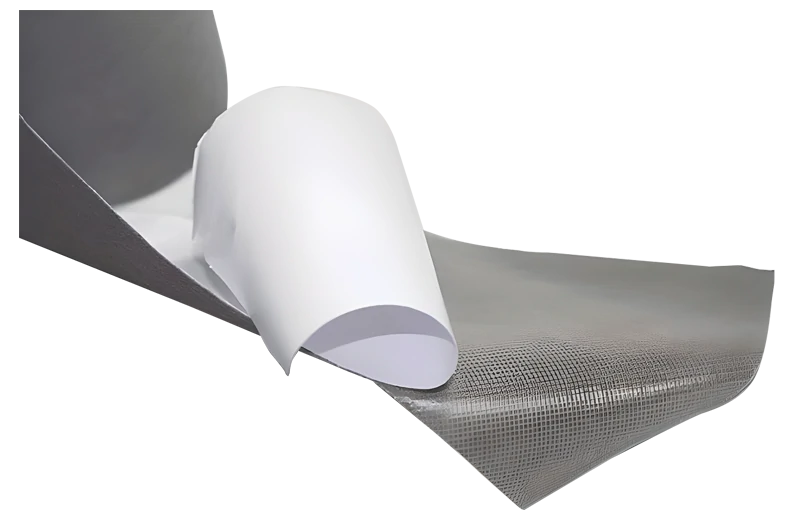

HVAC Aluminum Foil Tape is different from the traditional sense of the Duct Tape, is a special Duct tape use for Thermal Insulation outer wrapping of the Ducts. These tapes are single-faced adhesive tape of Aluminum Foil backing which is coated by Pressure-sensitive adhesive (PSA). Some varieties also include a fiberglass mesh for added strength.

The PSA that demonstrates superior bonding when exposed to both sub-zero and elevated temperatures. The shiny, UV resistant foil backing offers an enhanced appearance, excellent reflective and flame retardant properties, and remains flexible to resist cracking and lifting around irregular or curved surfaces. Aluminum foil tape is excellent at resisting moisture and vapor, helping to prevent mold and moisture damage. This tape is designed to last for long periods, often as long as the ductwork itself, without peeling, cracking, or deteriorating.

-

Here is a table comparing the two types of tape:

| Feature | HVAC Aluminum Foil Tape | Duct Tape |

| Material | Aluminum foil | Cloth or paper |

| Adhesive | Heat-resistant | General-purpose |

| Uses | Sealing joints in HVAC ductwork, insulating ductwork, protecting ductwork from the elements | Temporary repairs, sealing small leaks, holding things together |

| Durability | More durable | Less durable |

| Cost | More expensive | Less expensive |

Choosing between HVAC aluminum foil tape and duct tape depends largely on the application. For HVAC systems, aluminum foil tape is clearly the better choice due to its durability, effectiveness, and compliance with industry standards. However, duct tape can be a suitable option in certain situations, such as for temporary repairs or in less demanding environments.