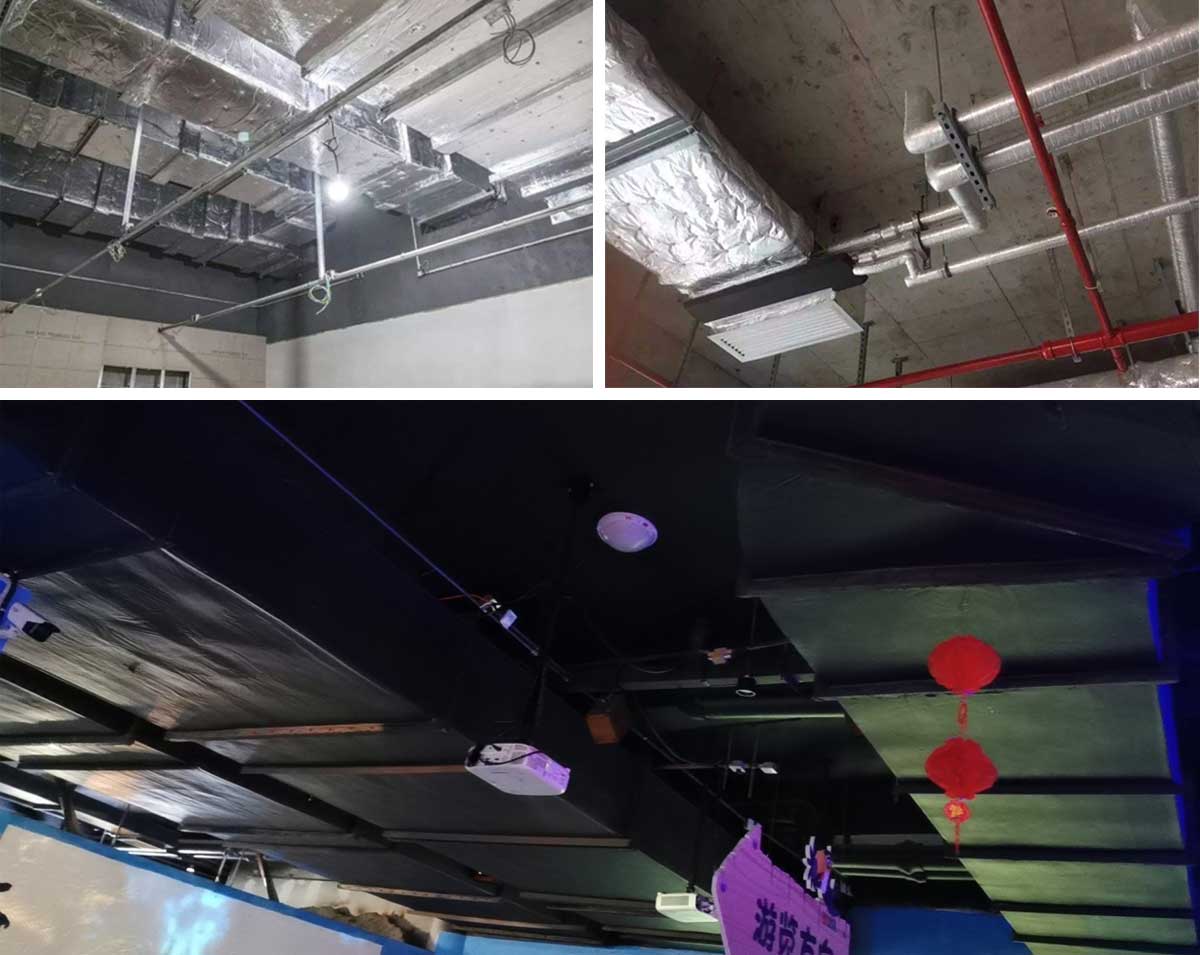

Aluminum foil tape is a preferred choice for HVAC ductwork due to its air sealing properties, moisture resistance, heat resistance, insulation support, flexibility, durability, and ease of application. By using aluminum foil tape in HVAC ductwork, it can enhance system efficiency, maintain indoor air quality, and ensure the long-term performance of the HVAC system by creating airtight and well-insulated ductwork.

Using aluminum foil tape for HVAC ductwork is a straightforward process, but it's essential to follow proper techniques to ensure a secure and effective seal. Following learn how to use foil tape for HVAC ductwork are designed to be applied for the best results.

Materials Needed

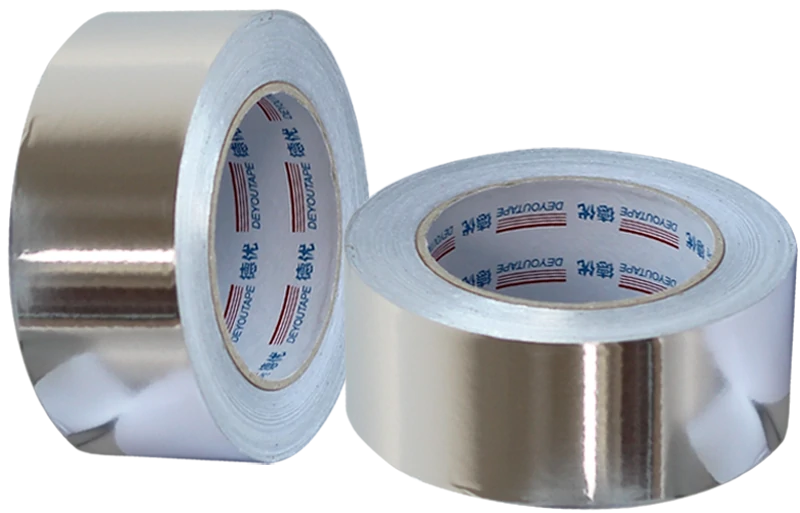

Aluminum foil tape (choose a high-quality tape specifically designed for HVAC use, ideally with an acrylic adhesive for long-term durability).

Utility knife or scissors.

Clean rag or cloth.

Steps of Using foil tape for HVAC ductwork:

1. Preparation:

Before applying the aluminum foil tape, ensure that the surface of the ductwork is clean and free of dust, debris, grease, or moisture. Cleaning the surface will help the adhesive tape adhere better and create a more reliable seal.

2. Cutting the Tape:

Cut or tear the length of aluminum foil tape that you need. If sealing a longer length of material, apply straight from the tape roll, only unrolling a few inches at a time to make handling easier.

3. Peeling off the Backing:

Remove the foil ductwork tape liner starting from the end you are using. This can be done by folding down a corner of the foil ductwork tape and peeling back the liner as you apply the tape.

4. Applying the Tape:

Position the tape over the joint, seam, or connection that needs to be sealed on the ductwork. Press the tape firmly onto the surface, starting from one end and working your way to the other end. Use your fingers or a roller to ensure the tape adheres smoothly and securely.

5. Sealing Joints and Seams:

Apply the aluminum foil tape along ductwork joints, seams, and connections where air leaks may occur. Make sure to cover the entire area that needs sealing, overlapping the tape if necessary to create a continuous barrier.

6. Smoothing and Pressing:

After applying the tape, use your fingers or a roller to smooth out any wrinkles or air bubbles and ensure a tight seal. Apply pressure along the entire length of the tape to activate the adhesive and secure it in place. Don’t skip this important step!

7. Insulation Support:

If using the tape to secure insulation on the ductwork, wrap the insulation material with the tape, ensuring it is tightly sealed and held in place. This helps improve the thermal efficiency of the ductwork.

8. Inspecting the Seal:

Once the tape is applied, visually inspect the sealed area to ensure there are no gaps, tears, or loose edges. A proper seal should be smooth, tight, and free of any imperfections that could compromise its effectiveness.

Tips for Using Foil Tape

Use the Right Tape: Choose a high-quality, UL-listed aluminum foil tape designed specifically for HVAC applications to ensure the best performance and durability.

Work in a Well-Ventilated Area: If you are using any cleaning solvents, work in a well-ventilated area to avoid inhaling fumes.

Avoid Extreme Temperatures: Apply the tape at room temperature for best adhesion. Extreme heat or cold can affect the adhesive properties.

Avoid Stretching the Tape: When applying the tape, avoid stretching it as this can cause the tape to lift or fail over time.

Overlap Tape Strips: If you need to use multiple strips of tape, make sure to overlap them by at least half an inch to ensure a continuous seal.

Troubleshooting:

Tape Not Sticking: If the tape is not sticking well, it's likely due to a dirty or damp surface. Clean and dry the area thoroughly and try again.

Air Leaks: If you still detect air leaks after applying the tape, try applying another layer of tape or using a sealant to fill any gaps.

By following these steps and best practices, you can effectively use aluminum foil tape for HVAC ductwork to seal joints, seams, and connections, as well as support insulation, helping to improve the efficiency and performance of the HVAC system.

Deyou Tape high-quality aluminum foil tape products are certified by the Quality Management System and tested for fire resistance, waterproofing, and chemical & UV resistance. Contact us today for customized solutions tailored to your aluminum foil tape needs.