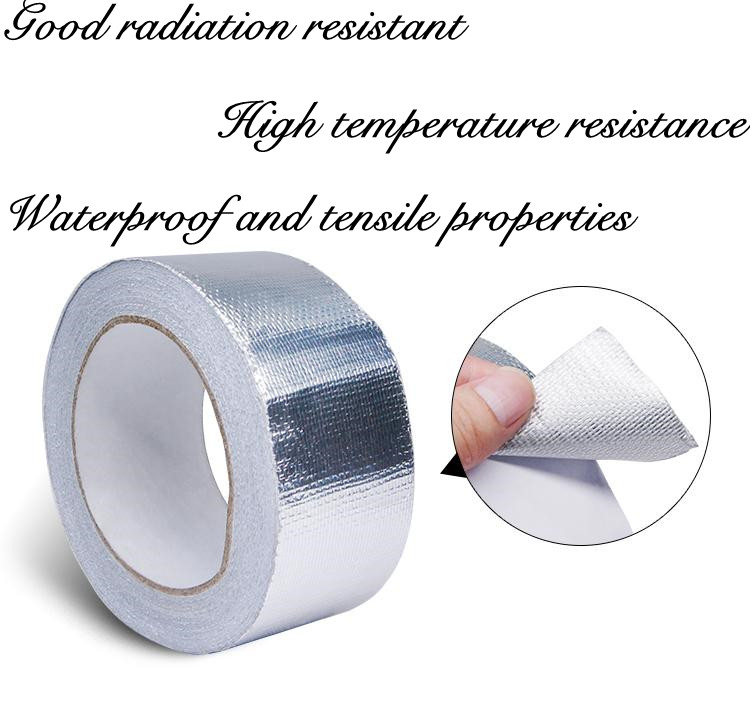

Aluminum foil tape is specifically designed for HVAC applications and provides excellent heat resistance and durability. It is commonly used to seal joints, seams, and connections in HVAC ductwork to prevent air leaks and improve energy efficiency.

Proper use aluminum foil tape is essential to ensure that all necessary components of the HVAC system are completely sealed and stitched together. The following steps can ensure the most effective way to use aluminum foil tapes to achieve complete system shutdown:

1. Prepare the surface

The surface that you will be applying the tape to must be clean, dry, and free of dirt, dust, and debris. If the surface is oily or greasy, you can clean it with a degreaser or rubbing alcohol.

2. Cut the tape to size

Cut or tear the length of the aluminum tape. If the aluminum tape is short enough to handle, if the material is long enough to seal, apply aluminum foil tapes directly from the roll of HVAC aluminum foil tape.

3. Peel the backing off the tape

If your aluminum foil tape has a liner, please remove the liner from the end you plan to use first.

4. Apply the tape to the surface

Apply the tape to the surface, starting at one end and overlapping the edges by about an inch. Press the tape firmly into place to ensure a good seal. Stick these aluminum foil tapes to the center of the sealing seam with a rubber scraper to keep aluminum foil tape in a non inked state on a smooth surface and consistent with the uneven or textured surface.

5. Smooth out any air bubbles

As you apply the tape, use your hand to gently smooth out any air bubbles trapped underneath to create a complete and secure seal.

6. Trim off any excess tape

Trim off any excess tape with a sharp knife or scissors.

7. Inspect the seal

Once you have applied the aluminum foil tape, inspect the seal to ensure there are no gaps or loose areas. Check for any visible signs of air leakage or gaps in the seal. If necessary, apply additional tape to reinforce the seal.

Additional Tips:

Overlaps: When using multiple pieces of tape for larger gaps, ensure they overlap each other by at least 1-2 inches (2.5-5 cm) for a continuous seal.

Corners: For corners, apply the tape with a slight bend or crease to allow better conformity around the corner and prevent gaps.

Always refer to the manufacturer's instructions and guidelines for specific recommendations on using aluminum foil tapes for HVAC sealing, as different tapes may have slightly different application techniques.