When sealing range hood ducts, it's crucial to use a tape that can withstand high temperatures, moisture, and grease. Here are some options:

-

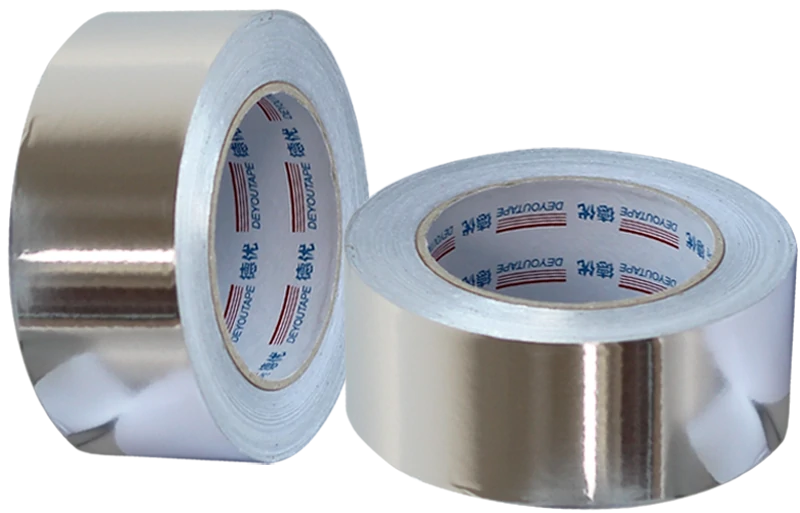

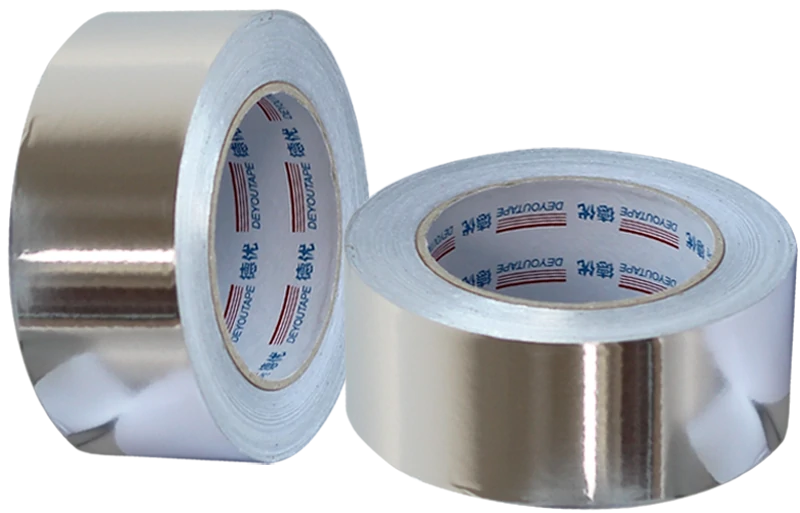

Aluminum Foil Tape

Advantages: Highly resistant to heat, moisture, and grease. Can withstand temperatures up to 400°F (204°C).

Best for: Sealing gaps and joints in ductwork, especially in areas exposed to high heat and moisture. -

Duct Tape

Advantages: Strong adhesive, versatile, and relatively inexpensive.

Best for: General-purpose sealing, but may not be as heat-resistant as aluminum foil tape. -

Butyl Tape

This is another suitable option, particularly for sealing joints that require a more durable, water-tight seal. Butyl tape is very sticky and provides a permanent seal that is highly resistant to weather and temperature extremes. -

Silicone Caulk

Advantages: Creates a durable, weatherproof seal. Can be used for both sealing and insulating ducts.

Best for: Sealing larger gaps or cracks in ductwork.

When choosing a tape, consider the following factors:

- Temperature: Ensure the tape can withstand the high temperatures generated by your range hood.

- Moisture resistance: The tape should be able to resist moisture from cooking and condensation.

- Grease resistance: The tape should be able to withstand exposure to grease and oils.

- Ease of application: Choose a tape that is easy to apply and adheres well to the ductwork.

For optimal sealing and performance, it's often recommended to use a combination of tape and caulk. Apply caulk to larger gaps or cracks, and then use tape to seal the edges and joints.

Aluminum foil tape is generally the best choice for sealing range hood vents. It's highly resistant to heat, moisture, and grease, making it ideal for this application.

How Use Aluminum foil tape to seal the range hood vent?

To use aluminum foil tape to seal a vent, follow these steps:

1. Prepare the Surface: Ensure that the surface around the vent is clean and dry. Wipe away any dust, dirt, or moisture to allow the tape to adhere properly.

2. Cut the Tape: Cut the aluminum foil tape to the desired length, allowing some extra length to ensure complete coverage of the vent seams.

3. Apply the Tape: Carefully apply the aluminum foil tape over the seams of the vent, pressing it firmly to ensure a secure bond. Smooth out any wrinkles or air bubbles to create a tight seal. If you’re not confident in the first layer of aluminum foil tape for range hood, just apply a second layer.

4. Inspect the Seal: After applying the tape, inspect the seal to ensure that all seams are covered and that there are no gaps or loose edges.

5. Test the Seal: Once the tape is applied, you can test the seal by running the ventilation system and feeling around the taped areas for any air leaks. If you detect any leaks, apply additional tape as needed.

By following these steps, you can effectively use aluminum foil tape to seal a vent, helping to prevent air leaks and improve the efficiency of the ventilation system.