Aluminum foil seam tape is specifically designed for sealing and joining seams in aluminum foil-faced insulation materials, such as vapor barriers. It is commonly used in construction and HVAC (Heating, Ventilation, and Air Conditioning) applications to create an airtight seal and prevent the passage of air, moisture, and vapor through the seams.

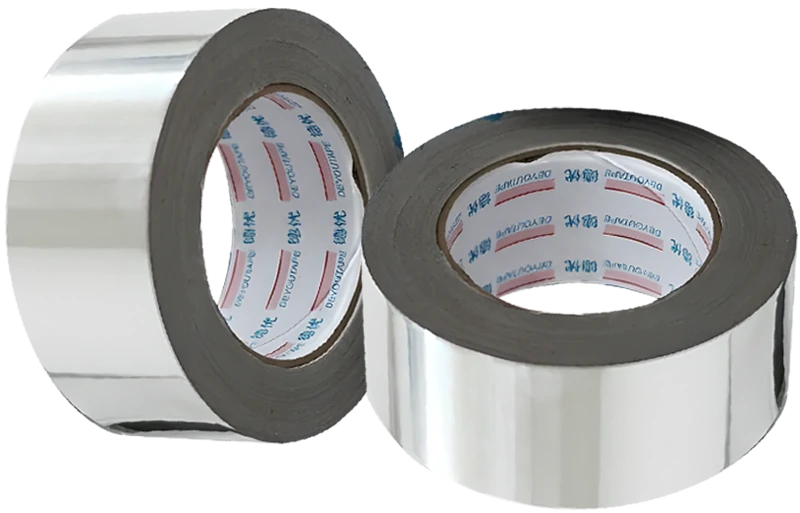

The alumium tape features a strong adhesive backing that bonds to various surfaces, and the aluminum foil provides a barrier against heat, light, and moisture. Some versions are also designed to be used in high-temperature environments, making them ideal for sealing ducts, pipes, and other areas that need to resist both heat and potential water damage.

Key Features:

Aluminum Foil Backing: Provides a strong vapor barrier, preventing moisture and air leakage. Reflects radiant heat, contributing to energy efficiency. Offers some degree of thermal conductivity.

Adhesive: Typically a pressure-sensitive adhesive, designed to bond strongly to various surfaces. The quality of the adhesive is crucial for long-term performance.

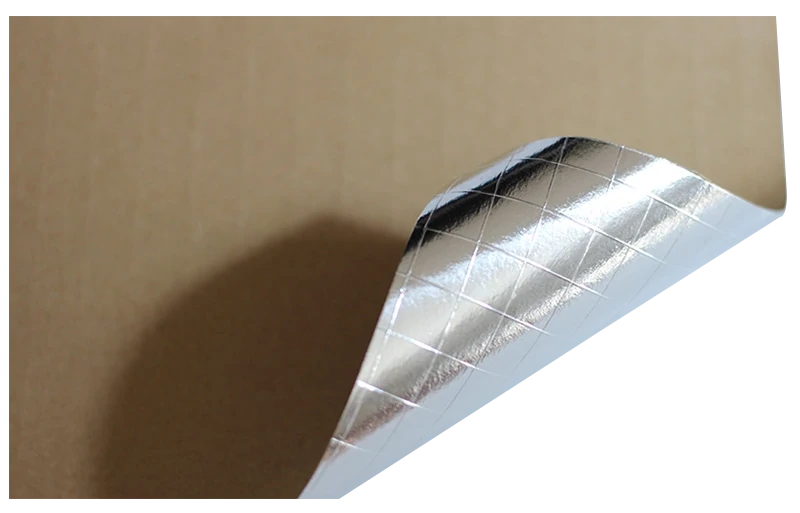

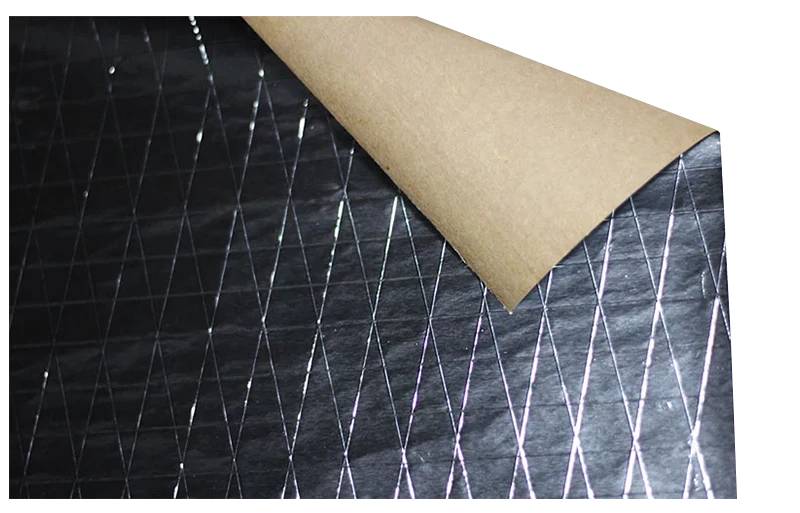

Scrim Reinforcement (Sometimes): Some aluminum foil seam tapes include a reinforcing scrim (e.g., fiberglass mesh) for added strength and tear resistance.

How to Choose Best Aluminum Foil Seam Tape for Vapor Barrier:

1. Understand the Application:

Indoor vs. Outdoor: Outdoor applications or areas with high humidity require a tape with superior moisture resistance and UV stability. Indoor applications may have less stringent requirements.

Temperature Range: Consider the temperature extremes to which the tape will be exposed Some tapes are rated for wider temperature ranges than others.

Surface Type: Ensure the tape is compatible with the surfaces you'll be sealing (e.g., foil-faced insulation, polyethylene sheeting, etc.).

2. Adhesive Strength

The adhesive should be strong enough to adhere to various surfaces, such as metal, wood, concrete, or insulation. It must create a durable bond that won't peel off under temperature fluctuations, moisture, or pressure. Opt for a tape with a high-performance, rubber-based or acrylic adhesive, as these materials offer long-lasting adhesion and resistance to moisture and temperature extremes.

3. Temperature Resistance

Aluminum foil seam tape is often used in areas exposed to high temperatures. Make sure the tape can handle the temperature range required for your application, especially if you're using it for ducts, pipes, or areas that may experience heat fluctuations.

4. Moisture and Vapor Barrier Effectiveness

For a vapor barrier, you need a tape that effectively seals out moisture and prevents water vapor from penetrating. Choose a tape designed specifically for sealing vapor barriers or one labeled as "vapor-proof." This ensures that it can withstand both moisture and air exposure over time.

5. Durability

The tape should be highly durable and resistant to wear and tear. Consider the conditions where the tape will be applied (e.g., indoor vs. outdoor, high-traffic areas). Look for tapes that are tear-resistant and UV-resistant if they will be exposed to sunlight.

6. Thickness of the Foil

A thicker aluminum foil layer will generally provide a more effective barrier against vapor, heat, and air. It also adds to the durability of the tape. For heavy-duty sealing, choose aluminum foil tape with a thicker gauge (around 3 mils or more).

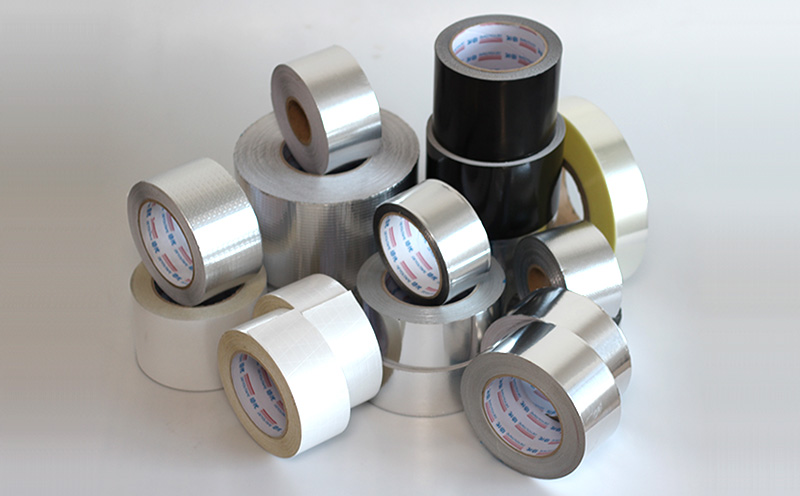

7. Width and Length of the Tape

Consider the size of the seams or gaps you’re sealing. A wider tape might be needed for larger seams or areas that require more coverage.

8. Ease of Application

Some tapes come with a split-back liner, which makes them easier to handle and apply. Ensure the tape is easy to cut, peel, and apply without too much effort.

9. Brand Reputation and Reviews

Choose reputable brands with positive user reviews, especially those that specialize in vapor barrier applications or HVAC systems.

10. Compliance with Standards

Ensure the tape meets industry standards for vapor barriers or sealing HVAC ducts, which might include UL ratings or ASTM certifications.

When choosing aluminum foil seam tape for vapor barriers, prioritize strong adhesion, moisture resistance, temperature resistance, and durability. Consider the specific environment in which the tape will be used and make sure the product is designed for the task. A little extra investment in a high-quality tape can save you trouble down the line by ensuring a secure, long-lasting seal.